The challenge

To demonstrate how a simple switch from R-23/R-508 to Klea 473A can enable a sustainable solution for very low temperature SJJ environmental test chambers.

Goal: to transform SJJ’s service sector by minimising the GWP impact when selecting refrigerants for climatic test chambers.

The impact – SJJ, Steve JONES’ Words

SJJ System Services Ltd has a proud tradition of technical innovation and vast experience with cascade refrigeration systems within the environmental test chamber sector.

« We set ourselves to the highest quality standards in meeting the needs of our customers around the world. Increasingly, this means making choices that minimise our impact on the environment when it comes to selecting refrigerants. In Klea 473A, we have found a long-term environment-friendly solution with a GWP 1830 (AR4) as opposed to that of 14800 (AR4) GWP with R-23 ».

The benefit: the future-proof solution

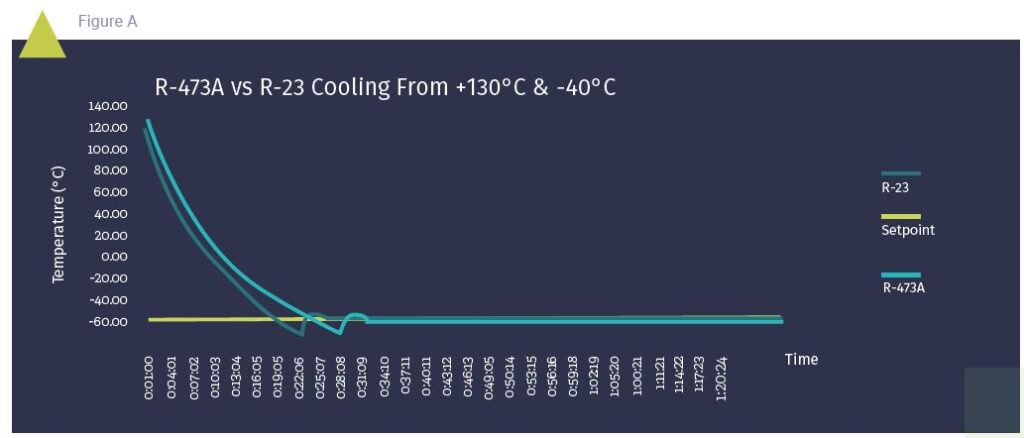

SJJ undertook some initial research and then launched a series of carefully controlled tests to assess the viability of Klea 473A as a very low GWP solution for the environmental test chambers. The tests demonstrated near-equivalent performance with Klea 473A vs R-23, see figure A, with slight expansion valve adjustment only. Klea 473A holds very low GWP future-proof refrigerant for ultra-low temperatures, down to -75 °C, in addition to the following benefits:

- Safety: A1 classification; non-flammable; non-toxic.

- Sustainability: provides SJJ with an F-Gas-compliant (90% GWP reduction vs R-23/R-508B) solution and the potential for a decreased Total Equivalent Warming Impact (TEWI) in line with the company’s environmental values.

- Compatibility: switch seamlessly with current compressor technology. SJJ is about to retrofit a system running on R-23 utilising a semi-hermetic and hermetic compressor.

SJJ Company and main points

SJJ System Services Limited was established in September 2015 by Mr. Steve Jones.

The small team is made of well-experienced staff, most with over 30 years of experience within the industry of environmental test chambers and have tested systems utilising cascade refrigeration systems from R-502/R-13 up to present days of R-404A/R-23/R-508.

With their extensive knowledge, they have the flexibility to be able to deal with all types of manufacturers of chambers working on all aspects of refrigeration systems. SJJ offers upgrades, refrigeration retrofit, and modification work, which can dramatically lower the GWP of test chambers, currently operating on refrigerants with high GWP such as R-23 at 14800.

The company is headquartered in the UK, but works across the world as and when required and is committed to minimising its impact on the environment through low GWP solutions.

SJJ works with R-23, but is aware that this is not suitable for the mid-long term.

The company is constantly looking for innovations in low GWP refrigerants, particularly with the expected phase-out of 2030 within the service sector of R-23. The introduction of Koura’s Klea 473A, interested SJJ who therefore embarked on a test programme to assess the refrigerant as a potential replacement for R-23 in its range of environmental test chambers. SJJ found in Klea 473A (R-473A) an optimal and future-proof solution for these applications.

Cooling and environmental needs

In considering the replacement for R-23, SJJ established the following key criteria:

- Identify a low GWP refrigerant to replace R-23 in support of its corporate values focused on minimising environmental impact.

- Find a solution compatible with current semi-hermetic and hermetic compressor technology.

- Ensure equivalent system capacity, energy efficiency, and performance without the need for any fundamental design change along with compatibility of lubricants within current installations.

- Fully assess the flammability and safety risks associated with “worst case” component failures or incorrect handling.

- Confirm the replacement refrigerant as a long-term, F-Gas-compliant solution, with the potential to extend into ultra low-temperature ranges and applications.

Test results

Using same charge of R-473A vs R-23, SJJ adopts the future-proof Klea 473A instead of R-23 for very low temperature applications in cascade climatic chambers.

SJJ benchmarked the performance of the system running R-23 with a rate of change at 10°C/min to enable detailed comparison. In this case, the original POE 32 oil was used in the compressor with no issues following eight months of operation.

SJJ looking for a sustainable future

As a result of the successful testing of Klea 473A, SJJ is introducing the refrigerant into their environmental test chambers. SJJ is satisfied with the results because with Klea 473A, the company can continue to serve its clients with the same performance with safety (A1, non-flammable), increased sustainability (90% reduction in GWP), and to provide peace of mind for users with a long-term refrigerant solution.

The Klea 473A solution

Klea 473A (R-473A) refrigerant is designed for very low temperatures, down to -75 °C in existing and new systems.

R-473A holds very low GWP: 90% reduction vs R-23/508. It is particularly suitable for applications that require a cold chain at ultra-low temperatures such as seafood transportation, as well as environmental chambers and biomedical freezers or transportation.

Koura has over 50 years of experience delivering trusted solutions, with innovation, sustainability, and customer focus driven approach. The latest innovation, Klea 473A is designed to achieve high performance with a significantly lower global warming potential to support the ever-increasing demand across the industry. Klea 473A is an A1 refrigerant by the ASHRAE SSPC34 committee.

In summary, Klea 473A is near drop-in with the same cooling capacity as R-23 with a near-equivalent refrigerant charge. Therefore, it is a long-term refrigerant solution for SJJ’s environmental test chambers range.

Klea 473A (R-473A) characteristics include:

• A1 Classification (non-flammable, non toxic) • No ODP • Chemically stable • Low glide • Low GWP : reduction by ca. 90 % vs R-23 / R-508B • Non-corrosive • Comply with the EU F-Gas regulation • Effective to at least -75°C

Drop-in test results without any technical modification :