John Bell, General Manager for J & E Hall in the Leeds region had just taken on a brand-new client working in the food manufacturing sector who had asked him to investigate an Ammonia system that was experiencing some issues with the oil.

On investigation it was identified that the problem was being caused by a mixture of different oils being used creating a wax like effect in the system. This was causing blockages and major running problems.

Turning to Climalife for advice, Dave Richards, the UK’s Head of Sales, suggested using Facilisolv® to clean the system.

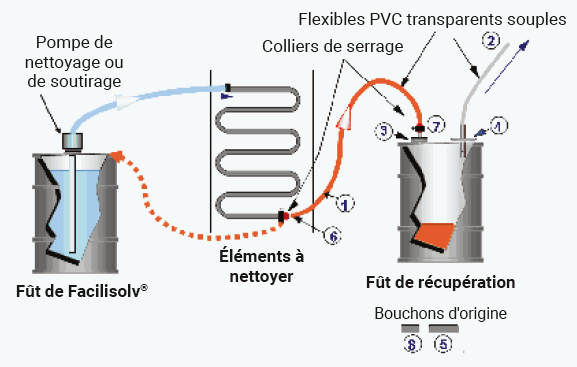

Facilisolv® : an internal cleaning solvent

Facilisolv® is a product designed for the internal cleaning of refrigeration and air conditioning refrigerant circuits in industrial use.

Developed by Climalife, it is an effective solvent that eliminate impurities from circuits using refrigerant fluids and standard refrigeration oils. Facilisolv® is highly compatible with a wide range of metals, plastic and elastomers.Developed by Climalife, it is an effective solvent that eliminate impurities from circuits using refrigerant fluids and standard refrigeration oils. Facilisolv® is highly compatible with a wide range of metals, plastic and elastomers.

Dave had witnessed the successful use of Facilisolv® on a system of a very similar nature so had no hesitation in suggesting it for this project.

A thorough cleaning process

The cleaning process involved recovering the ammonia by emptying the installation, and then rinsing the refrigeration circuit with clear water until it reached a pH level of over 7.

The circuit was then cleaned and degreased using Facilisolv®. Modifications were performed to ensure the installation was functioning correctly before the ammonia was reloaded. Guidance from the product data and safety data sheets was followed at all times.

Upon completing the work, Mr Bell described the product as : « very easy to use and extremely effective, dissolving the wax providing an ideal solution to the problem. The problem was cleared in a very short time allowing the Leeds J&E Hall Service Team to have the system running again quickly with no impact to the customers production ».

PLUS

Mr Bell had no hesitation in recommending Facilisolv® 100% to other users.